Climate Action Roadmap Showcase | Tackling emissions in the supply chain | Reducing emissions in transport and logistics | Driving towards net zero properties | Changing consumer behaviour

Reducing waste

Waste can come in many forms, from lost material in the manufacturing process, food which has expired, or unnecessary packaging that ends up in landfill. Reducing such wate not only can lower carbon emissions, but save money in operations and reduce landfill. This category is about cutting that waste – food or non-food - produced through retailer operations. For example, moving to more recyclable / compostable materials, removing single-use materials from products and packaging, or making productive use of waste such as food waste for fuel / compost.

currys

dreams

LEARN MORE

Dreams’ Recovery Centre is a purpose-designed facility established to receive customer product returns and restore them to a ‘good as new’ condition for resale. The centre was created to enable Dreams to continue to offer a generous returns policy to customers, without driving excess consumption and landfill waste that harms the planet.

Before the Recovery Centre was established in September 2013, Dreams’ process of receiving used products, assessing their condition, and concluding whether to resell them at a clearance store or dispose of them, was inefficient and ineffective, meaning approximately 30% of returned beds and mattresses were discarded.

The centre has been extremely successful. Now, over 90% of Dreams customer returns are recovered and resold. What’s more, the sale of products restored by the Recovery Centre has generated enough additional profit to fund broader recycling and sustainability efforts across the business, enabling Dreams to send 0 materials to landfill for 8 consecutive years.

The creation, development, and momentum sustained around the Recovery Centre is indicative of Dreams’ sustainability focussed culture and paves the way for further improvement to come over the next few years.

M&S

n brown

LEARN MORE

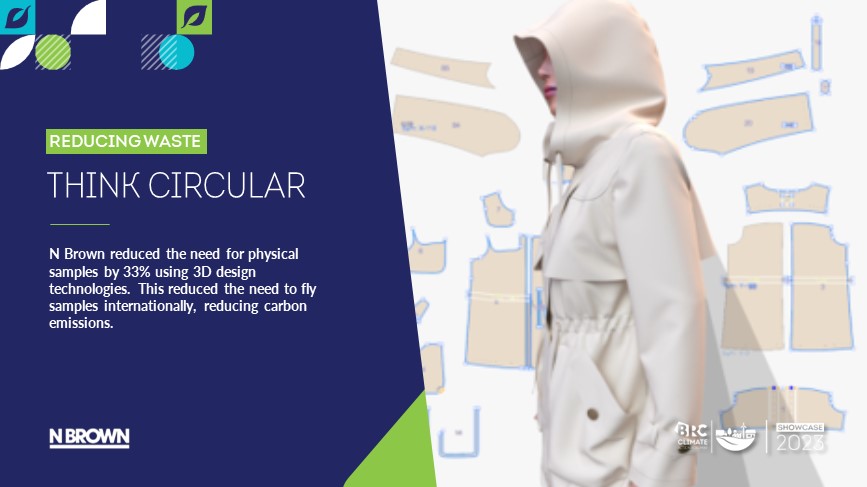

Our approach to clothing design is centred around a “think circular and right first time” approach. Technology in retail is highly focused on the front end online experience but within product development its use is highly fragmented. We would typically receive three physical samples from suppliers when designing new products that would be sent via air freight. We have taken an innovative stance to use cutting edge technology to reduce the need for physical samples within the product development stage – all in support of our sustainability strategy.

We have been investing in digital product development for a number of years. The process begins with using data from body scans to create unique 3D avatars to simulate the variety of fabrics, customer body shapes and sizes, enabling 3D design and fit of the perfect style for our customer. Our ability to design products digitally, change colours and prints, and more, in the 3D environment has reduced the need for physical samples.

In 2022, we decided to invest in additional Browzwear 3D software licences to allow us to implement digital sampling across our jersey wear lines and therefore reduce the need for physical sample production further. We focused on our Bangladesh suppliers with support from our Bangladesh office to ensure smooth implementation.

We’ve seen a reduction in samples of approximately 1,700 this Spring Summer 23 season, which is a 33% reduction in samples which would otherwise have been produced and sent via air freight. Our use of technology within the product design process is playing a part in making fashion more sustainable and we continue to innovate in this space to increase our impact.

new look

LEARN MORE

Operational waste is one of the few areas in scope 3 emissions where businesses have direct control. As such New Look began an initiative to tackle waste within our operations, identifying our warehouse and stores as key target areas.

The project began by assessing current processes and packaging use within our operations, quickly noting unnecessary and over-engineered packaging. In addition, utilising our partners expertise, a waste management plan was introduced to increase recycling rates in the DC. New Look has also worked to re-engineer internal packaging, reducing the thickness of plastic, and increasing recycled content used throughout.

Within stores, a closed loop system for clear plastic packing has been implemented whereby all packaging is backhauled through our logistics partners and recycled through known routes where the material is reused within our ecommerce mailer and carrier bag production. This initiative needs continuous engagement with the retail teams to ensure its effectiveness throughout the year.

Through these initiatives, New Look has made significant savings both in cost and carbon emissions, this year reducing waste by 922 tonnes and reducing carbon emissions from store and DC waste by 20%.

simba sleep